Clad Pipe

Combining high strength, corrosion resistance and cost-effectiveness.

Clad Pipe

Combining Strength, Corrosion Resistance, Safety, and Cost-Effectiveness

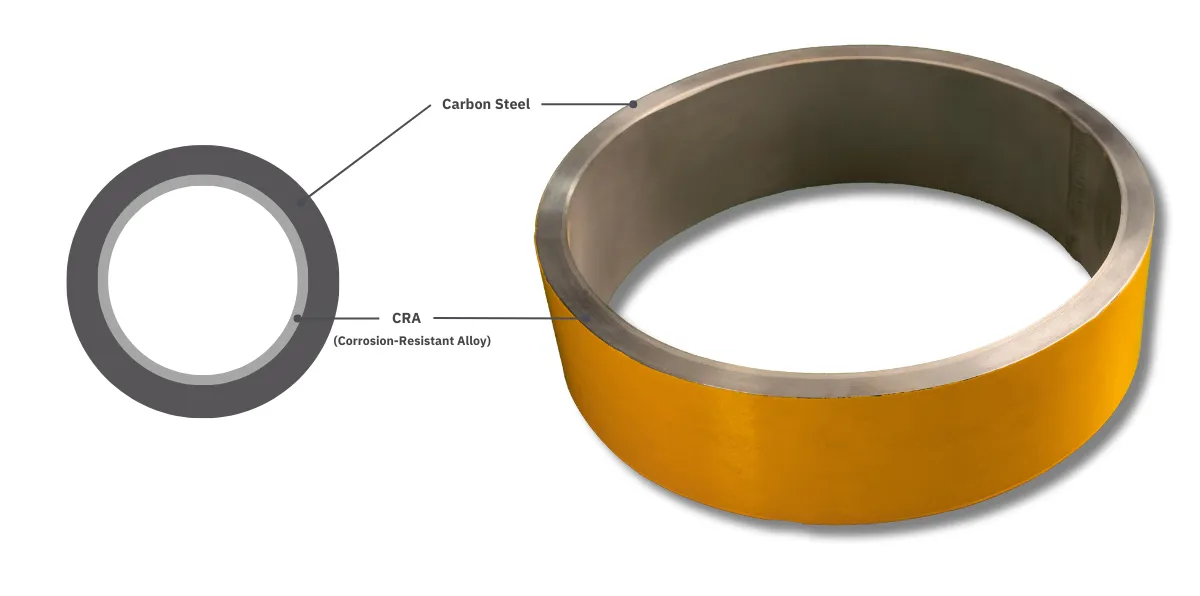

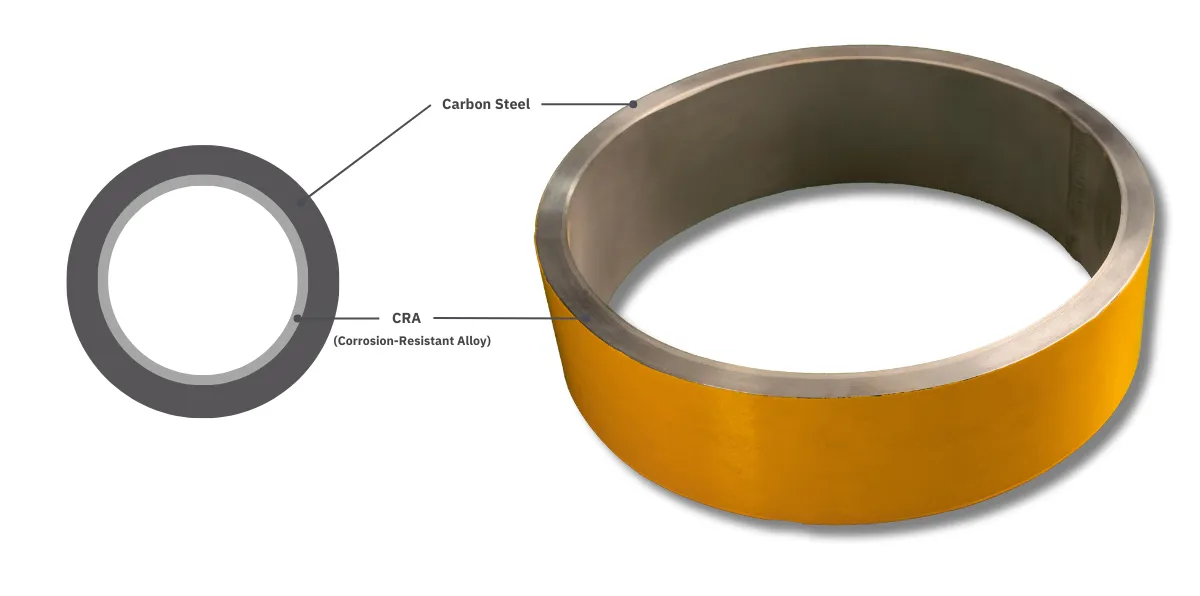

Our clad pipes are manufactured from advanced explosion-welded clad plates using JCO manufacturing process and longitudinal seam welding process. These pipes provide users with safe and reliable properties, offering excellent strength and superior corrosion resistance in a variety of demanding industries and applications.

Combining Strength, Corrosion Resistance, Safety, and Cost-Effectiveness

Our clad pipes are manufactured from advanced explosion-welded clad plates using JCO manufacturing process and longitudinal seam welding process. These pipes provide users with safe and reliable properties, offering excellent strength and superior corrosion resistance in a variety of demanding industries and applications.

|

Explosion-welded clad

|

|

Clad Pipe Specifications

—————— - - -

|

Explosion-welded clad Through medium-frequency induction bending, we can bend clad pipes with diameters ranging from168mm to 1422mm (6''–56'') up to 180°, ensuring precise dimensional control for seamless integration into pipeline systems. Additionally, we offer induction bends made from solid corrosion-resistant materials. |

|

| Explosive-Welded Clad Pipe | Performance Comparison | Pure Alloy Pipe |

| Yes | Reduce material costs | No |

| Yes | Decrease wall thickness to reduce weight | No |

| Explosive-Welded Clad Pipe | Overlay-Welded Clad Pipe | |

| Yes | Improve the internal surface condition | No |

| Yes | Ensure uniform chemical composition of the cladding layer (no base material dilution) | No |

| Yes | N06625 can be used as the cladding layer | No |

| Yes | Higher cost-performance ratio | No |

| Yes | Faster production efficiency | No |

| Explosive-Welded Clad Pipe | Lined Pipe | |

| Yes | For higher technical requirements (such as risers, elbows, etc.) |

No |

| Yes | The pipeline can be installed through winding | No |

| Yes | Allowing for larger sizes (higher diameters and thicknesses). |

No |

|

Explosion-welded clad

|

|

Clad Pipe Specifications

—————— - - -

|

Explosion-welded clad Through medium-frequency induction bending, we can bend clad pipes with diameters ranging from168mm to 1422mm (6''–56'') up to 180°, ensuring precise dimensional control for seamless integration into pipeline systems. Additionally, we offer induction bends made from solid corrosion-resistant materials. |

|

| Explosive-Welded Clad Pipe | Performance Comparison | Pure Alloy Pipe |

| Yes | Reduce material costs | No |

| Yes | Decrease wall thickness to reduce weight | No |

| Explosive-Welded Clad Pipe | Overlay-Welded Clad Pipe | |

| Yes | Improve the internal surface condition | No |

| Yes | Ensure uniform chemical composition of the cladding layer (no base material dilution) | No |

| Yes | N06625 can be used as the cladding layer | No |

| Yes | Higher cost-performance ratio | No |

| Yes | Faster production efficiency | No |

| Explosive-Welded Clad Pipe | Lined Pipe | |

| Yes | For higher technical requirements (such as risers, elbows, etc.) |

No |

| Yes | The pipeline can be installed through winding | No |

| Yes | Allowing for larger sizes (higher diameters and thicknesses). |

No |