Clad Pipe

High Strength, Corrosion Resistance & Cost Efficiency

Clad Pipe

China CRA Cladded Pipe with Advanced Cladding Solutions

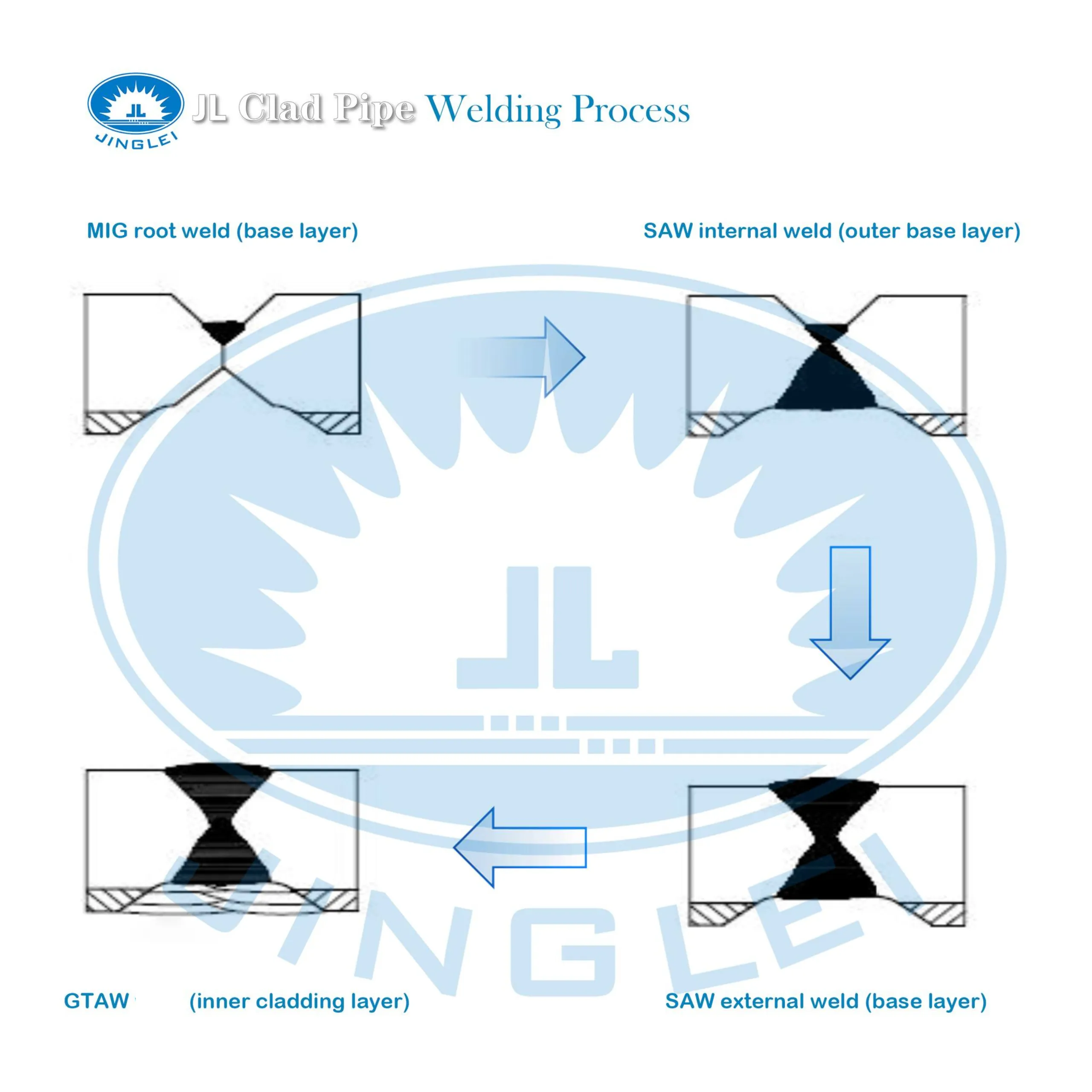

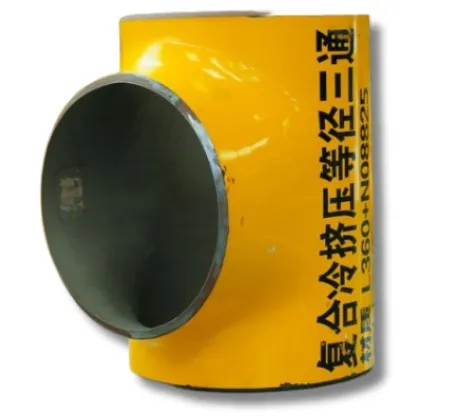

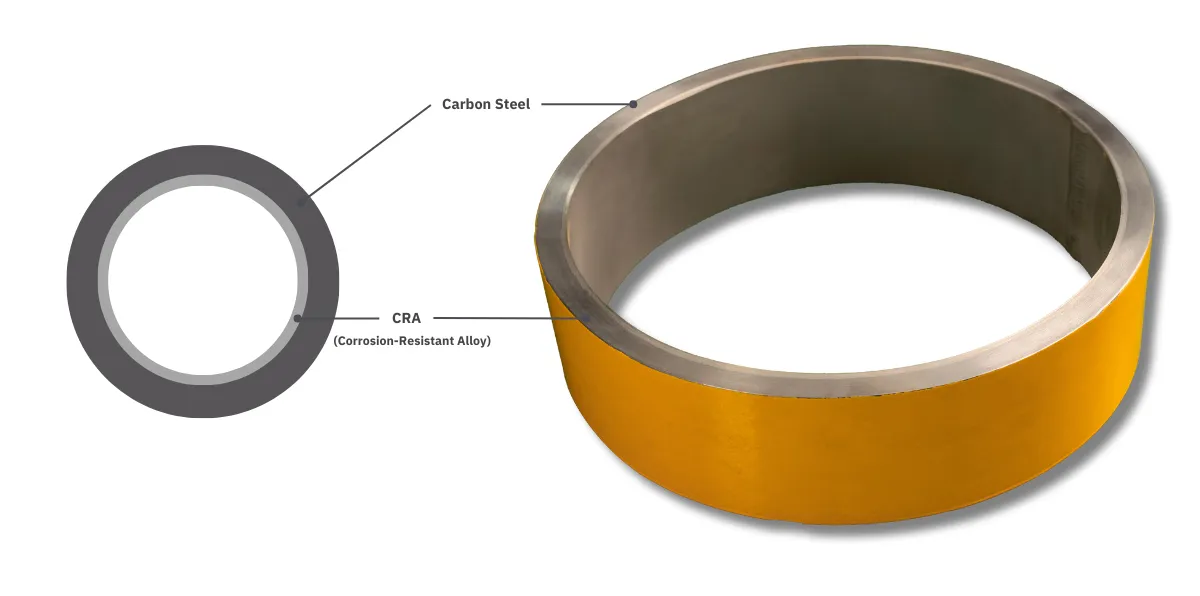

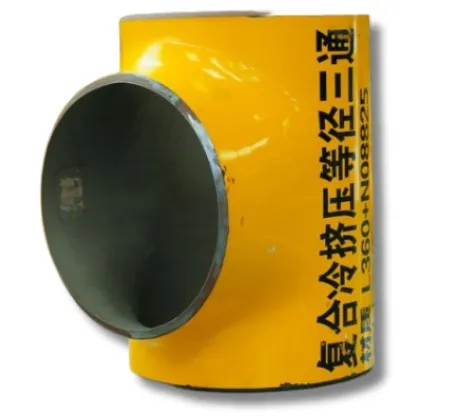

Our cladded pipes are manufactured from advanced explosion-welded clad plates using the JCO forming process and longitudinal seam welding, ensuring consistent metallurgical integrity and dependable performance. We offer a variety of pipe fittings such as tees, elbows, induction bends, and other clad pipe fittings, delivering fully customized service throughout the entire process. All products are available in a wide range of pipe cladding options, including 304 stainless steel, duplex stainless steel, inconel 625, incoloy 825, Alloy C276, titanium (Ti), and other corrosion-resistant clad systems, providing excellent mechanical strength, superior corrosion resistance, and long-term reliability for oil, gas, chemical, and petrochemical industries.

China CRA Cladded Pipe with Advanced Cladding Solutions

Our cladded pipes are manufactured from advanced explosion-welded clad plates using the JCO forming process and longitudinal seam welding, ensuring consistent metallurgical integrity and dependable performance. We offer a variety of pipe fittings such as tees, elbows, induction bends, and other clad pipe fittings, delivering fully customized service throughout the entire process. All products are available in a wide range of pipe cladding options, including 304 stainless steel, duplex stainless steel, inconel 625, incoloy 825, Alloy C276, titanium (Ti), and other corrosion-resistant clad systems, providing excellent mechanical strength, superior corrosion resistance, and long-term reliability for oil, gas, chemical, and petrochemical industries.

|

|

|

|

|

|

Challenge Facing ▪ Highly Corrosive Media (Gas or Liquid). (CO₂ corrosion, Cl⁻ corrosion, H₂S corrosion) ▪ High-Pressure Conditions. Operating pressure exceeds 10 MPa ▪ High-Temperature Conditions. Operating temperature exceeds 100°C ▪ Challenges for Pipeline Materials. - Pure alloy pipelines are costly to construct. - Pure carbon steel pipelines are prone to corrosion failure, leading to significant economic loss

Solutions ▪ Corrosion Resistance ▪ Withstands HighTemperature and Pressure ▪ Safe and Reliable Performance ▪ Cost-Effective Over the Full Life Cycle

|

|

Through medium-frequency induction bending, we can bend clad pipes with diameters ranging from 168mm to 1422mm (6''–56'') up to 180°, ensuring precise dimensional control for seamless integration into pipeline systems. Additionally, we offer induction bends made from solid corrosion-resistant materials. By applying localized closed-loop temperature-controlled softening to the pipe, we achieve plastic deformation of the material and form a smooth, continuous pipe curvature. Compared to traditional mitered welded elbows, this process significantly improves the transmission efficiency of media such as oil, gas, and chemicals. It is particularly suitable for complex conditions involving sour oil and gas or highly corrosive fluids, making it the preferred choice for high-reliability pipeline systems in the energy and chemical industries.

|

|

|

|

|

| Clad Induction Bends | Pressed Clad Elbows | Cold-Extruded Clad Equal Tees |

Drawn Four-Way Clad Tees |

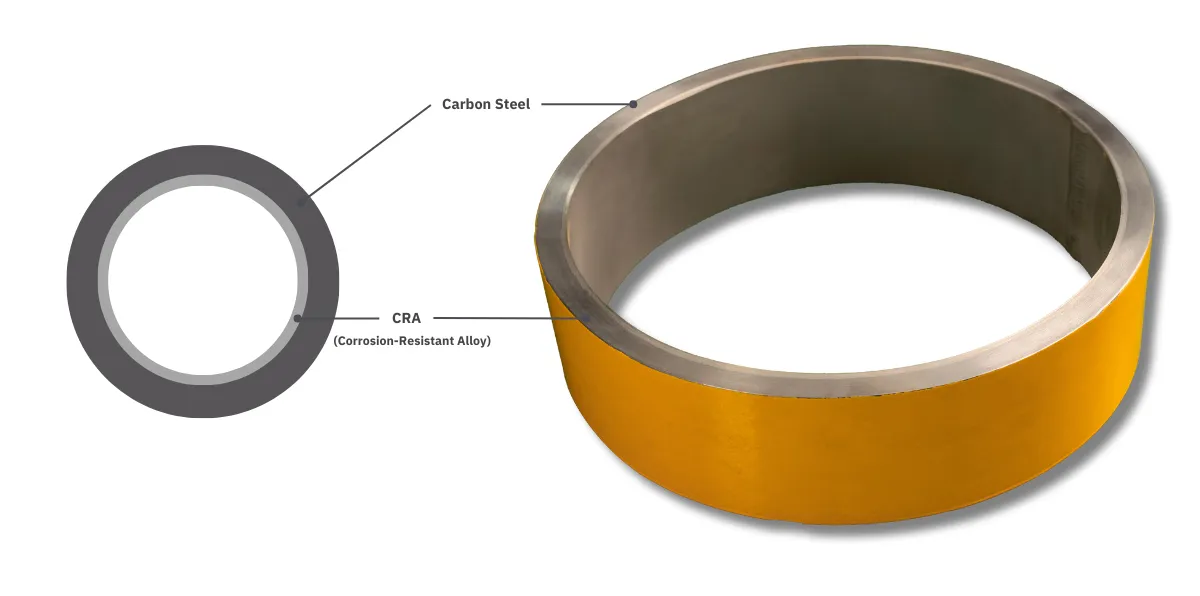

Clad pipe cross-sectionalsample |

| Explosive-Welded Clad Pipe | Performance Comparison | Pure Alloy Pipe |

| Yes | Reduce material costs | No |

| Yes | Decrease wall thickness to reduce weight | No |

| Explosive-Welded Clad Pipe | Overlay-Welded Clad Pipe | |

| Yes | Improve the internal surface condition | No |

| Yes | Ensure uniform chemical composition of the cladding layer (no base material dilution) | No |

| Yes | N06625 can be used as the cladding layer | No |

| Yes | Higher cost-performance ratio | No |

| Yes | Faster production efficiency | No |

| Explosive-Welded Clad Pipe | Lined Pipe | |

| Yes | For higher technical requirements (such as risers, elbows, etc.) |

No |

| Yes | The pipeline can be installed through winding | No |

| Yes | Allowing for larger sizes (higher diameters and thicknesses). |

No |

- — Manufacturing ability & Technical advantage

Since 2010, the production of high-quality longitudinally welded clad pipes has become a core focus of Jinglei’s business.

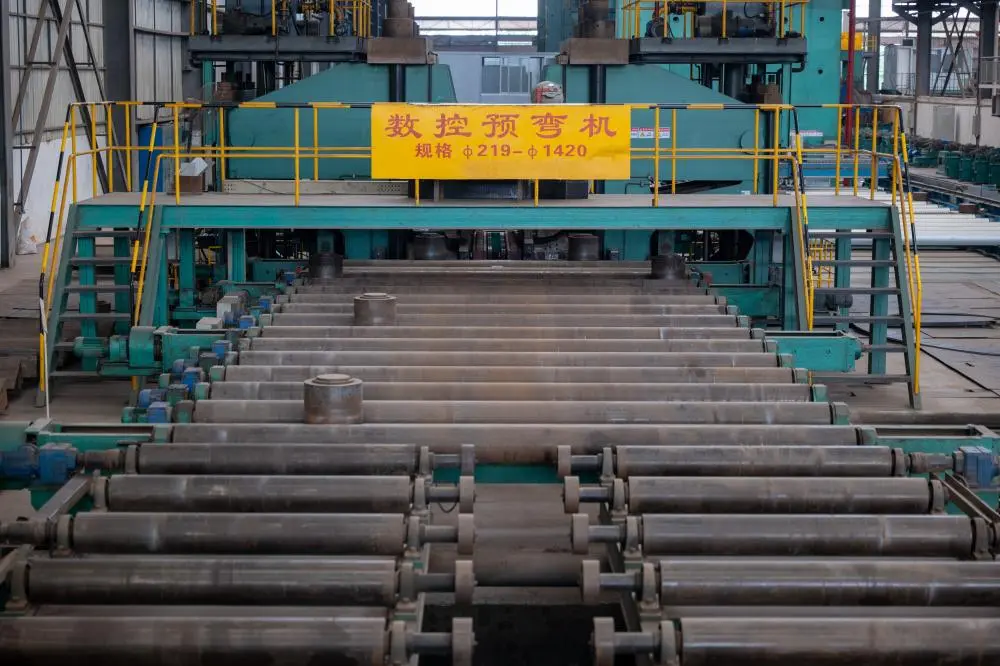

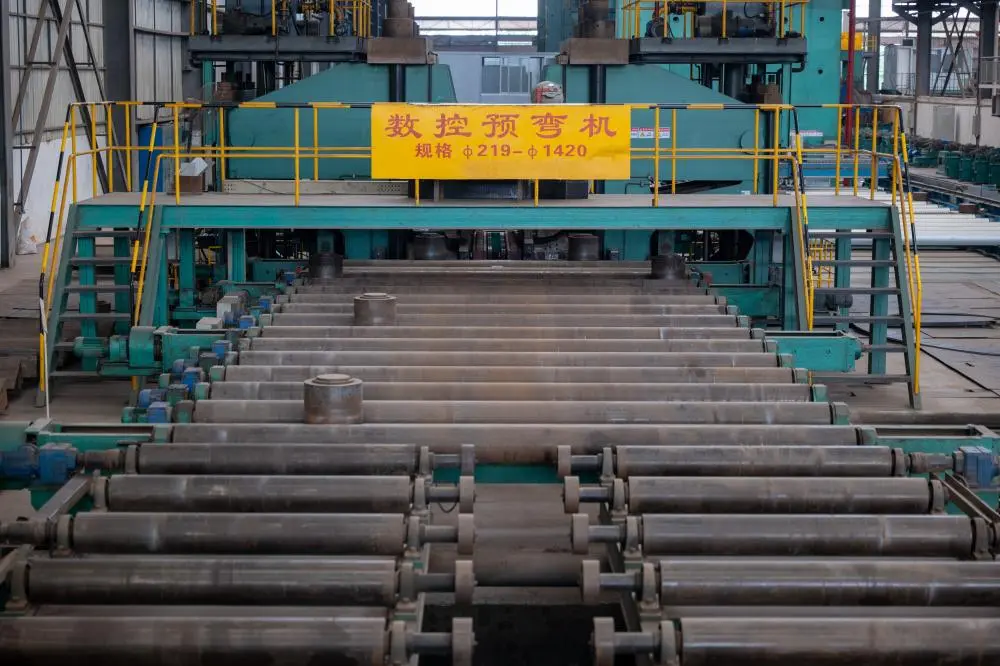

The clad pipe production line independently developed by our company supports large-scale manufacturing with pipe diameters ranging from 168 mm to 2000 mm and single pipe lengths up to 12 meters, ranking among the top in the industry in terms of processing range and precision. As the first domestically developed clad pipe production line with fully independent intellectual property rights, it integrates four core process systems:

The innovatively developed laser tracking seam alignment process achieves combination precision of ±0.1mm. The intelligent bending system ensures efficient forming for pipes of various specifications. Multi-dimensional composite inspection technology enables high standard defect detection rates. With full process digital control and an intelligent quality traceability system, the product qualification rate exceeds 99.5%, providing high-reliability, cost-effective corrosion-resistant pipeline solutions for harsh environments, such as deep-sea oil and gas development and high-sulfur gas applications.

|

|

|

|

| Tandem Twin-Wire Welding Machine | Clad Pipe Outer Welding Machine | Auto Ultrasonic Testing Equipment | TIG Inner Welding Machine |

|

|

|

|

|

| 5200T CNC Press Brake | CNC Pipe Forming Machine | CNC Pre-Bending Machine | CNC High-Speed Edge Milling Machine | Hydrostatic Testing Machine |

|

|

|

|

|

|

Challenge Facing ▪ Highly Corrosive Media (Gas or Liquid). (CO₂ corrosion, Cl⁻ corrosion, H₂S corrosion) ▪ High-Pressure Conditions. Operating pressure exceeds 10 MPa ▪ High-Temperature Conditions. Operating temperature exceeds 100°C ▪ Challenges for Pipeline Materials. - Pure alloy pipelines are costly to construct. - Pure carbon steel pipelines are prone to corrosion failure, leading to significant economic loss |

|

Solutions ▪ Corrosion Resistance ▪ Withstands HighTemperature and Pressure ▪ Safe and Reliable Performance ▪ Cost-Effective Over the Full Life Cycle |

Through medium-frequency induction bending, we can bend clad pipes with diameters ranging from 168mm to 1422mm (6''–56'') up to 180°, ensuring precise dimensional control for seamless integration into pipeline systems. Additionally, we offer induction bends made from solid corrosion-resistant materials. By applying localized closed-loop temperature-controlled softening to the pipe, we achieve plastic deformation of the material and form a smooth, continuous pipe curvature. Compared to traditional mitered welded elbows, this process significantly improves the transmission efficiency of media such as oil, gas, and chemicals. It is particularly suitable for complex conditions involving sour oil and gas or highly corrosive fluids, making it the preferred choice for high-reliability pipeline systems in the energy and chemical industries.

|

|

|

| Clad Induction Bends | Pressed Clad Elbows | Cold-Extruded Clad Equal Tees |

|

|

| Drawn Four-Way Clad Tees | Clad pipe cross-sectionalsample |

The company offers induction bends, elbows, tees, and other clad pipe fittings, and provides factory prefabricated pipe sections based on customer isometric drawings and pipeline design models, achieving a fully customized service throughout the entire process.

| Explosive-Welded Clad Pipe | Performance Comparison | Pure Alloy Pipe |

| Yes | Reduce material costs | No |

| Yes | Decrease wall thickness to reduce weight | No |

| Explosive-Welded Clad Pipe | Overlay-Welded Clad Pipe | |

| Yes | Improve the internal surface condition | No |

| Yes | Ensure uniform chemical composition of the cladding layer (no base material dilution) | No |

| Yes | N06625 can be used as the cladding layer | No |

| Yes | Higher cost-performance ratio | No |

| Yes | Faster production efficiency | No |

| Explosive-Welded Clad Pipe | Lined Pipe | |

| Yes | For higher technical requirements (such as risers, elbows, etc.) |

No |

| Yes | The pipeline can be installed through winding | No |

| Yes | Allowing for larger sizes (higher diameters and thicknesses). |

No |

- — Manufacturing ability & Technical advantage

Since 2010, the production of high-quality longitudinally welded clad pipes has become a core focus of Jinglei’s business.

The clad pipe production line independently developed by our company supports large-scale manufacturing with pipe diameters ranging from 168 mm to 2000 mm and single pipe lengths up to 12 meters, ranking among the top in the industry in terms of processing range and precision. As the first domestically developed clad pipe production line with fully independent intellectual property rights, it integrates four core process systems:

The innovatively developed laser tracking seam alignment process achieves combination precision of ±0.1mm. The intelligent bending system ensures efficient forming for pipes of various specifications. Multi-dimensional composite inspection technology enables high standard defect detection rates. With full process digital control and an intelligent quality traceability system, the product qualification rate exceeds 99.5%, providing high-reliability, cost-effective corrosion-resistant pipeline solutions for harsh environments, such as deep-sea oil and gas development and high-sulfur gas applications.

|

|

|

|

| Tandem Twin-Wire Welding Machine | Clad Pipe Outer Welding Machine | Auto Ultrasonic Testing Equipment | TIG Inner Welding Machine |

|

|

|

|

|

| 5200T CNC Press Brake | CNC Pipe Forming Machine | CNC Pre-Bending Machine | CNC High-Speed Edge Milling Machine | Hydrostatic Testing Machine |