Clad Plate

Combining high strength, corrosion resistance, and cost-effectiveness.

Clad Plate

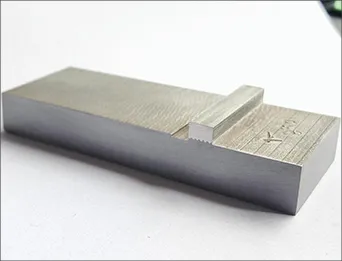

Explosion Welding (Blast Welding) Technology

China Jinglei’s explosion-bonded clad plates, are engineered to combine the strength of steel plate with the corrosion resistance of premium alloys, creating reliable clad metal plate solutions for harsh industrial environments. Our product range covers 304 stainless clad, SS 304, SS-201, duplex stainless steel, and a full selection of nickel-based alloys including inconel 625 (uns n06625), incoloy 825 (uns n08825), and Alloy C276, as well as titanium metal, Ti clad, chrom-nickel systems, and other nickel chromium alloy options. Our production capacity exceeds 200,000 tons annually.

Explosion Welding (Blast Welding) Technology

China Jinglei’s explosion-bonded clad plates, are engineered to combine the strength of steel plate with the corrosion resistance of premium alloys, creating reliable clad metal plate solutions for harsh industrial environments. Our product range covers 304 stainless clad, SS 304, SS-201, duplex stainless steel, and a full selection of nickel-based alloys including inconel 625 (uns n06625), incoloy 825 (uns n08825), and Alloy C276, as well as titanium metal, Ti clad, chrom-nickel systems, and other nickel chromium alloy options. Our production capacity exceeds 200,000 tons annually.

The company uses explosive cladding technology to mass-produce various types of metal clad plates, including stainless clad steel, nickel-based alloy clad steel, titanium clad steel, copper clad steel, zirconium clad steel, and tantalum clad steel. All mechanical properties and physical-chemical performance indicators fully comply with current national standards and international advanced standards, with key performance indicators (such as shear strength and bonding rate) being industry-leading.

| Percentage of Cost Savings Compared to Pure Alloy Plate | 10+3 (mm) | 20+3 (mm) | 30+3 (mm) | 40+3 (mm) | 50+3 (mm) | 60+3 (mm) | 70+3 (mm) | 80+3 (mm) |

| CS + UNS N06625 | 0.6 | 0.76 | 0.82 | 0.85 | 0.87 | 0.89 | 0.9 | 0.9 |

| CS + UNS N08825 | 0.55 | 0.7 | 0.77 | 0.8 | 0.82 | 0.83 | 0.84 | 0.85 |

| CS + SS6L | 0.35 | 0.5 | 0.56 | 0.59 | 0.61 | 0.62 | 0.63 | 0.64 |

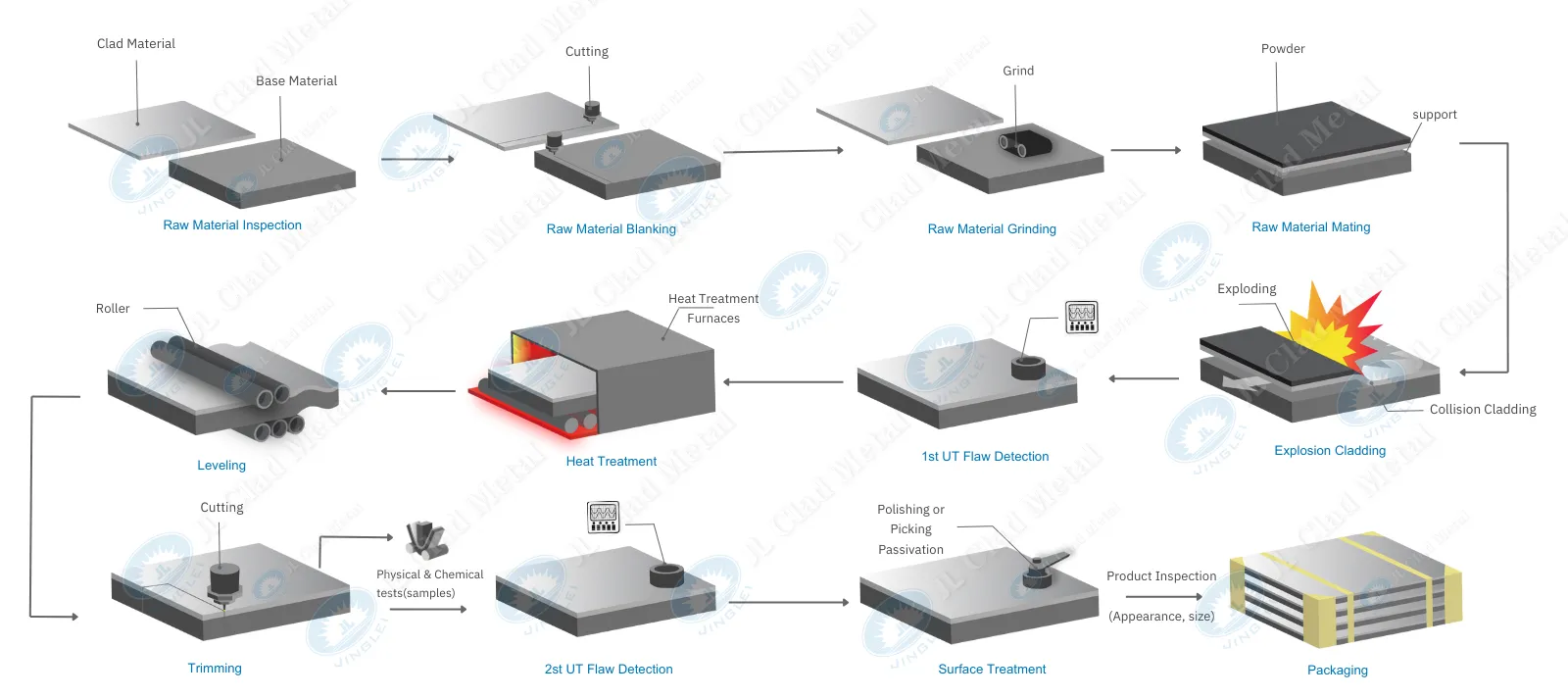

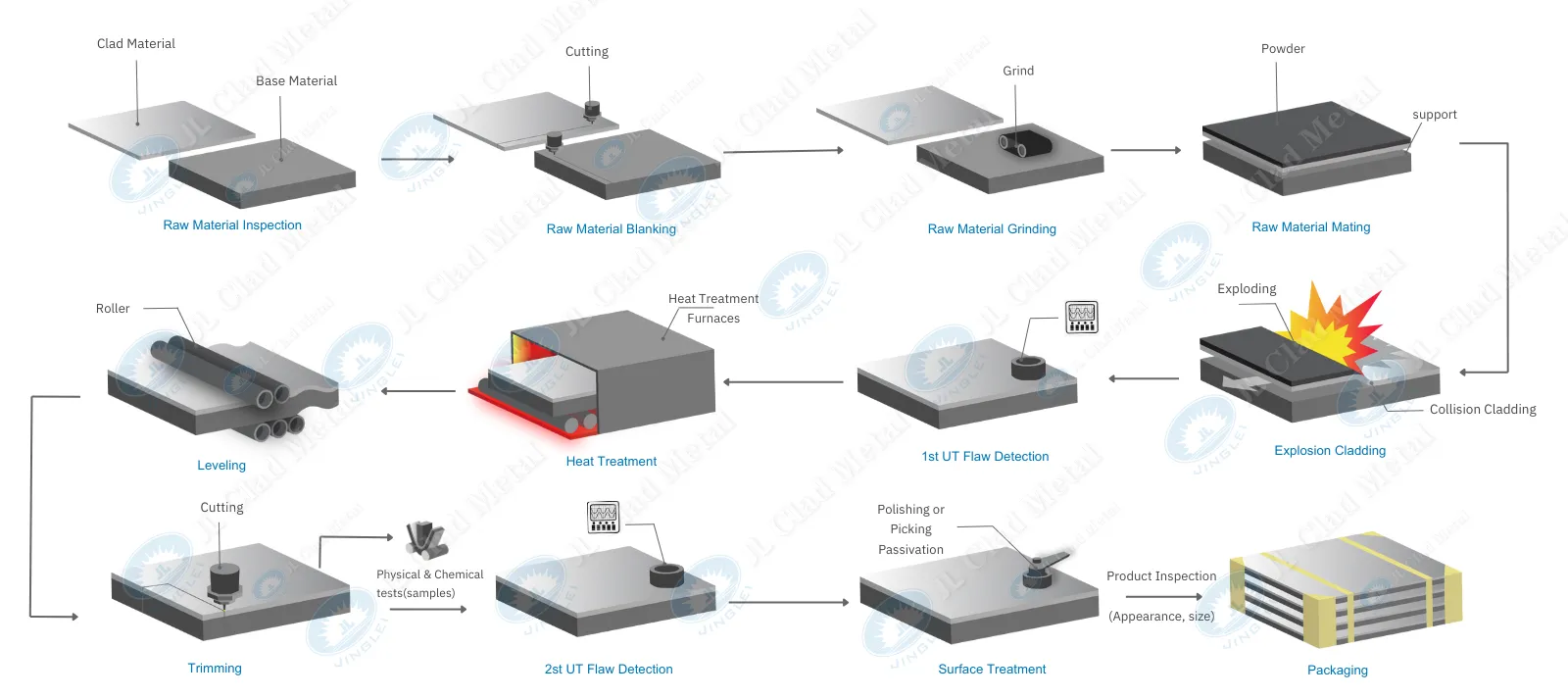

During explosion welding, detonation drives the cladding plate to collide with the base plate at high speed. This collision under extreme temperature and pressure enables atomic diffusion bonding and forms a continuous wavy interface. The high-velocity oblique impact creates a metal jet that removes surface impurities, achieving a clean interface and strong metallurgical bond between the two metals.

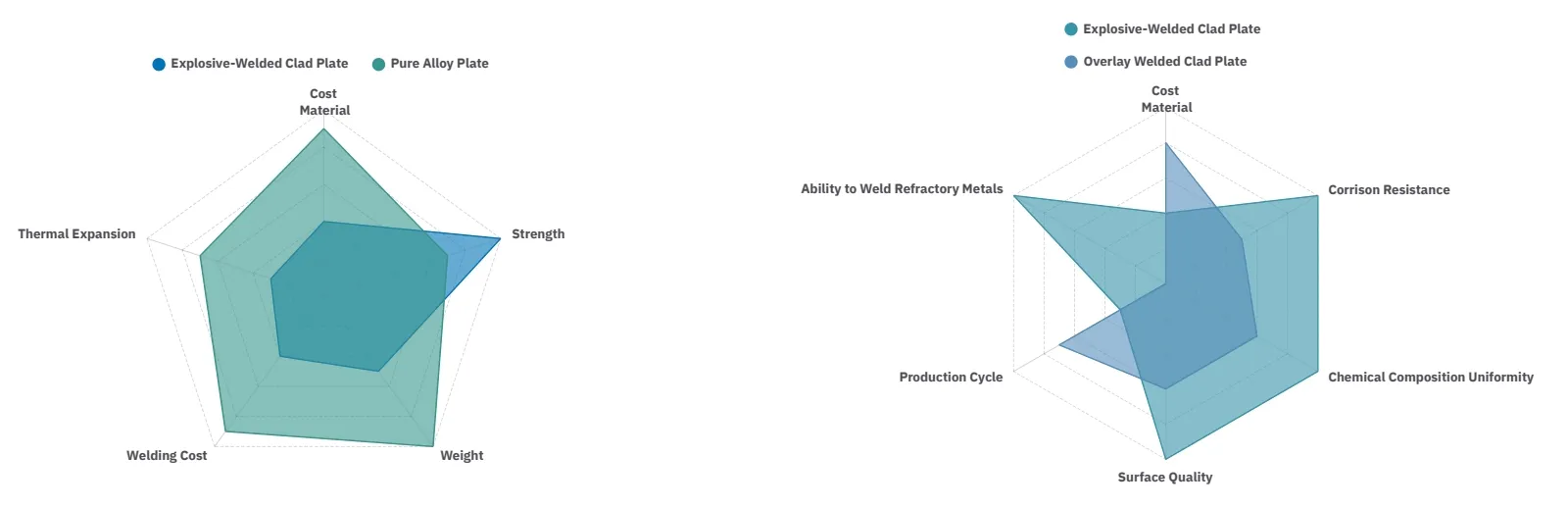

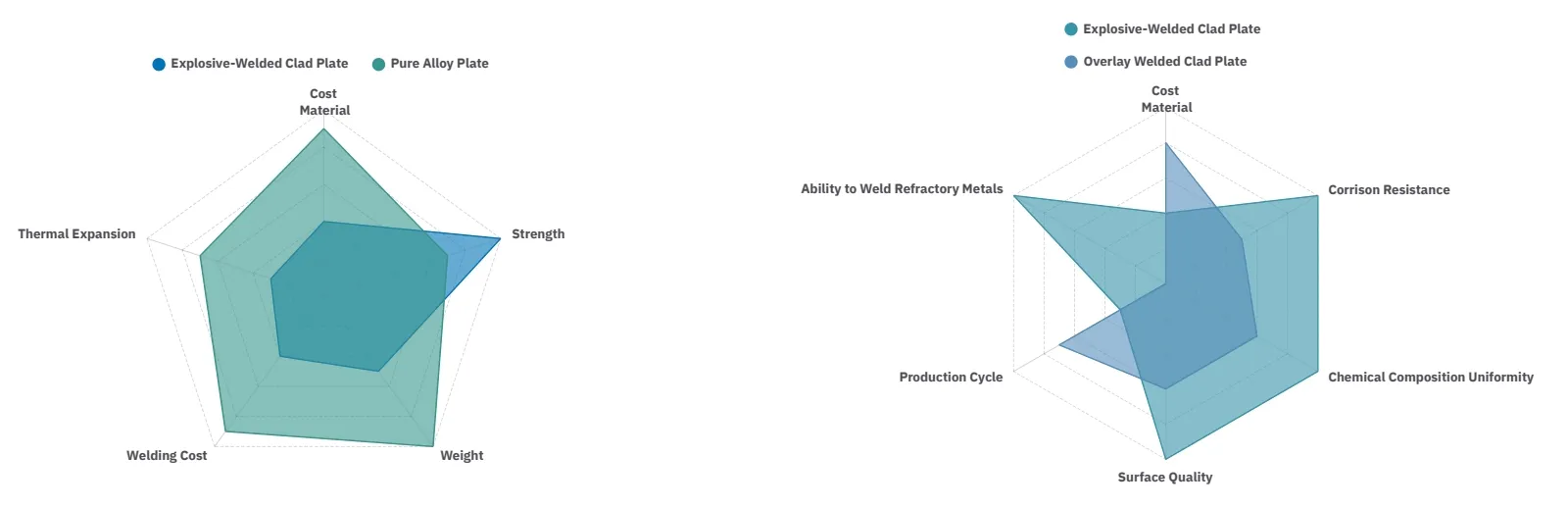

Compared with weld overlay, explosion welding simultaneously eliminates dilution-related strength loss and inconsistency in weld quality, delivering a uniform, high-integrity metallurgical bond across the entire clad surface.

The thickness design of the clad plate base material and cladding, material pairing, and specifications are flexible. They can be diversified according to different environmental requirements and can be produced in single specifications or in bulk.

|

01.Specifications and Dimensions: In addition to standard sizes, customized production is available for specific specifications and shapes. |

|

02.Material Pairing: A combination of various materials, such as carbon steel, stainless steel, and non-ferrous metals. |

|

03.Thickness Design: The base material to cladding thickness ratio typically exceeds 3:1. |

- — Performance Characteristics and Comparisons

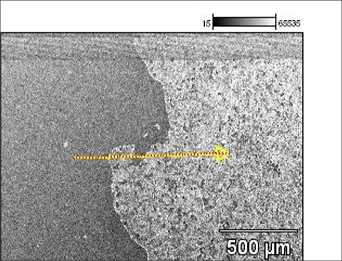

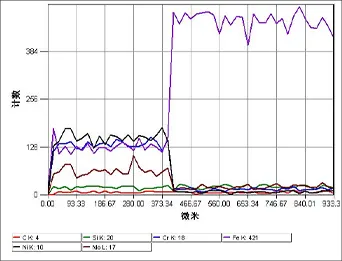

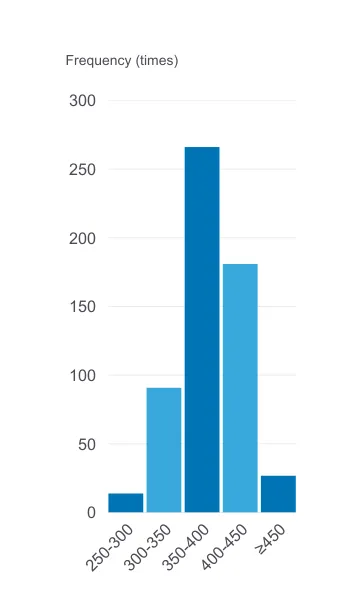

Using explosion welding technology, a metallurgical bond between the base metal and cladding metal is achieved, with an average shear strength at the bonding interface reaching 350 MPa, significantly exceeding the ASTM standard requirement (≥140 MPa).

|

|

|

|

|

|

| Interface Scanning Electron Microscopy (SEM) | Chemical Composition Analysis of Bonding Interface | Shear Strength Test | Torsion Test (1080°) | Outer Bending Test | Inner Bending Test |

|

Shear Strength (MPa) |

|

Material Item |

Clad Material |

Stainless Steel |

Carbon Steel + Coating |

Liner |

|

|

Quality Evaluation |

Safety |

Excellent |

Excellent |

Usable |

Usable |

|

Corrosion Resistance |

Excellent |

Excellent |

Usable |

Good |

|

|

Material Structure |

Excellent |

Excellent |

Usable |

Usable |

|

|

Application Scope |

Wide |

Wide |

Narrow |

Narrow |

|

|

Economic Evaluation |

Material Cost |

20% - 80% |

100% |

30% |

80% |

|

Construction |

Excellent |

Excellent |

Usable |

Usable |

|

|

Service Life |

Long |

Long |

Short |

Short |

|

The company uses explosion welding technology to mass-produce various types of metal clad plates, including stainless steel-steel, nickel-based alloy-steel, titanium-steel, copper-steel, zirconium-steel, and tantalum-steel. All mechanical properties and physical-chemical performance indicators fully comply with current national standards and international advanced standards, with key performance indicators (such as shear strength and bonding rate) being industry-leading.

| Percentage of Cost Savings Compared to Pure Alloy Plate | 10+3 (mm) | 20+3 (mm) | 30+3 (mm) | 40+3 (mm) | 50+3 (mm) | 60+3 (mm) | 70+3 (mm) | 80+3 (mm) |

| CS + Alloy625 | 0.6 | 0.76 | 0.82 | 0.85 | 0.87 | 0.89 | 0.9 | 0.9 |

| CS + Alloy825 | 0.55 | 0.7 | 0.77 | 0.8 | 0.82 | 0.83 | 0.84 | 0.85 |

| CS + SS6L | 0.35 | 0.5 | 0.56 | 0.59 | 0.61 | 0.62 | 0.63 | 0.64 |

The company uses explosion welding technology to mass-produce various types of metal clad plates, including stainless steel-steel, nickel-based alloy-steel, titanium-steel, copper-steel, zirconium-steel, and tantalum-steel. All mechanical properties and physical-chemical performance indicators fully comply with current national standards and international advanced standards, with key performance indicators (such as shear strength and bonding rate) being industry-leading.

The thickness design of the clad plate base material and cladding, material pairing, and specifications are flexible. They can be diversified according to different environmental requirements and can be produced in single specifications or in bulk.

|

01.Specifications and Dimensions: In addition to standard sizes, customized production is available for specific specifications and shapes. |

|

02.Material Pairing: A combination of various materials, such as carbon steel, stainless steel, and non-ferrous metals. |

|

03.Thickness Design: The base material to cladding thickness ratio typically exceeds 3:1. |

- — Performance characteristics and comparisons

Using explosion welding technology, a metallurgical bond between the base metal and cladding metal is achieved, with an average shear strength at the bonding interface reaching 350 MPa, significantly exceeding the ASTM standard requirement (≥140 MPa).

|

|

|

|

Material Item |

Clad Material |

Stainless Steel |

Carbon Steel + Coating |

Liner |

|

|

Quality Evaluation |

Safety |

Excellent |

Excellent |

Usable |

Usable |

|

Corrosion Resistance |

Excellent |

Excellent |

Usable |

Good |

|

|

Material Structure |

Excellent |

Excellent |

Usable |

Usable |

|

|

Application Scope |

Wide |

Wide |

Narrow |

Narrow |

|

|

Economic Evaluation |

Material Cost |

20% - 80% |

100% |

30% |

80% |

|

Construction |

Excellent |

Excellent |

Usable |

Usable |

|

|

Service Life |

Long |

Long |

Short |

Short |

|