Pressure Vessel

For many years, our company has been a reliable supplier of various types of tower vessels, horizontal vessels, heat exchangers, and other high-pressure vessels.

Pressure Vessel

China Advanced Clad Pressure Vessel Equipments

As a A1, A2 and ASME certified china manufacturer of clad pressure vessels, Jinglei Technology integrates design, fabrication, installation, and inspection under a rigorous quality management system. Our vessels adopt engineered clad shells and metal clad construction where appropriate, ensuring that the applied cladding delivers enhanced corrosion resistance and long-term durability in demanding operating environments.

China Advanced Clad Pressure Vessel Equipments

As a A1, A2 and ASME certified china manufacturer of clad pressure vessels, Jinglei Technology integrates design, fabrication, installation, and inspection under a rigorous quality management system. Our vessels adopt engineered clad shells and metal clad construction where appropriate, ensuring that the applied cladding delivers enhanced corrosion resistance and long-term durability in demanding operating environments.

|

|

|

|

|

| Manufacture Standards | ASME VIII DIV.I,GB150,GB151 |

| Diameter | 4500mm Max |

| Wall Thickness | 300mm Max |

| Total Length (Height) | 48000mm Max |

| Unit Weight | 400T Max |

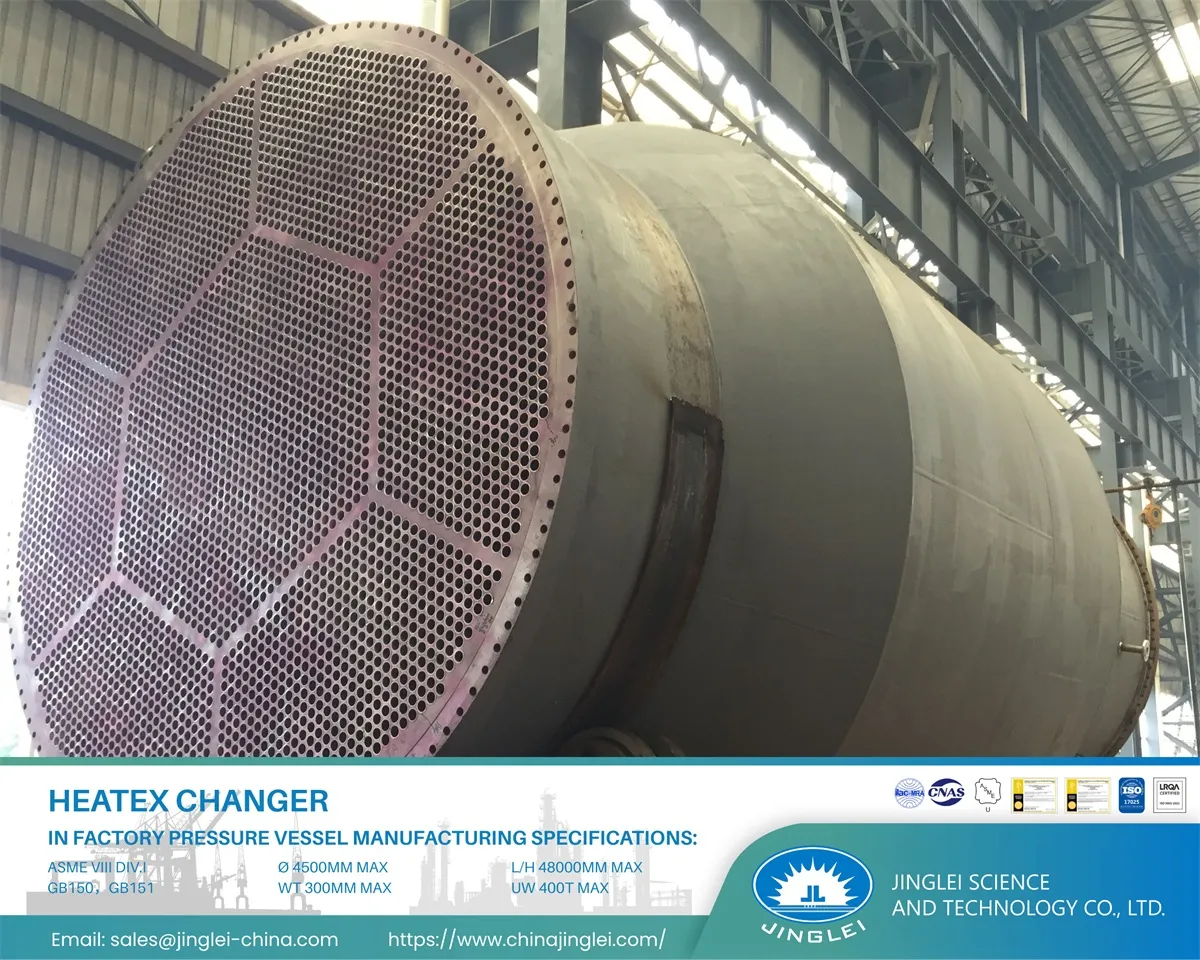

- — Heat Exhanger

As a specialized manufacturer in the field of pressure vessels, our company has established a comprehensive manufacturing system for high-efficiency heat exchange equipment.

In response to demanding operating conditions, we focus on the production of large shell-and-tube heat exchangers using titanium and titanium alloy tubes, achieving a strong competitive advantage in corrosive environments such as saline-alkali chemical processing and wastewater treatment. For applications requiring enhanced corrosion protection, we also provide heat exchanger cladding solutions that extend service life in severe chemical and thermal processes. In particular, within multi-effect vacuum evaporation and MVR evaporation systems, we have delivered a wide range of efficient and reliable heat exchangers—including systems integrated with liquid-to-liquid heat exchanger configurations and specialized liquid heat exchanger loops—that significantly improve user performance.

As a highly efficient and dependable thermal exchange device, shell-and-tube heat exchangers are widely used across various industries due to their excellent heat transfer performance and compact structure.

|

|

|

|

|

- — Storage Tank

The company has extensive experience in the field of storage tank and possesses professional on-site construction capabilities. We are capable of manufacturing and installing storage tanks and tank clusters with capacities ranging from 100m³ to 120,000m³. We have produced hundreds of various types of storage tanks for industries such as petrochemical, new energy chemicals, new materials, and water treatment.

|

|

|

|

|

- — Other Products List

Based on years of experience, we also provide a wide range of pressure vessels and auxiliary equipment, such as LPG Tanks, Amine Solution Activated Carbon Filters, Gas-Liquid Separators, Secondary Sulfur Condensers, Vacuum Towers, Feed Gas Heat Exchangers, Oxidized Asphalt Atmospheric Towers, Main Hydrocracking Reactors, High-Pressure Flash Drums, Slag Crushers, and Shift Gas Amine Scrubber Towers, covering diverse process requirements from petroleum refining to coal chemical industries.

| Product Name | Application Filed |

| Amine Solution Activated Carbon Filter | Chemical and petrochemical industries |

| Gas-Liquid Separator | Oil and gas extraction |

| Secondary Sulfur Condenser | Sulfur recovery units |

| Vacuum Tower | Refining and chemical industries |

| Feed Gas Heat Exchanger | Natural gas processing, refining, petrochemicals |

| Oxidized Asphalt Atmospheric Tower | Petroleum refining industry |

| Main Hydrocracking Reactor | Refining industry |

| High-Pressure Flash Drum | Oil refining and chemical industries |

| Slag Crusher | Coal chemical industry |

| Shift Gas Amine Scrubber Tower | Coal chemical industry |

| Other |

|

|

|

|

|

| Manufacture Standards | ASME VIII DIV.I,GB150,GB151 |

| Diameter | 4500mm Max |

| Wall Thickness | 300mm Max |

| Total Length (Height) | 48000mm Max |

| Unit Weight | 400T Max |

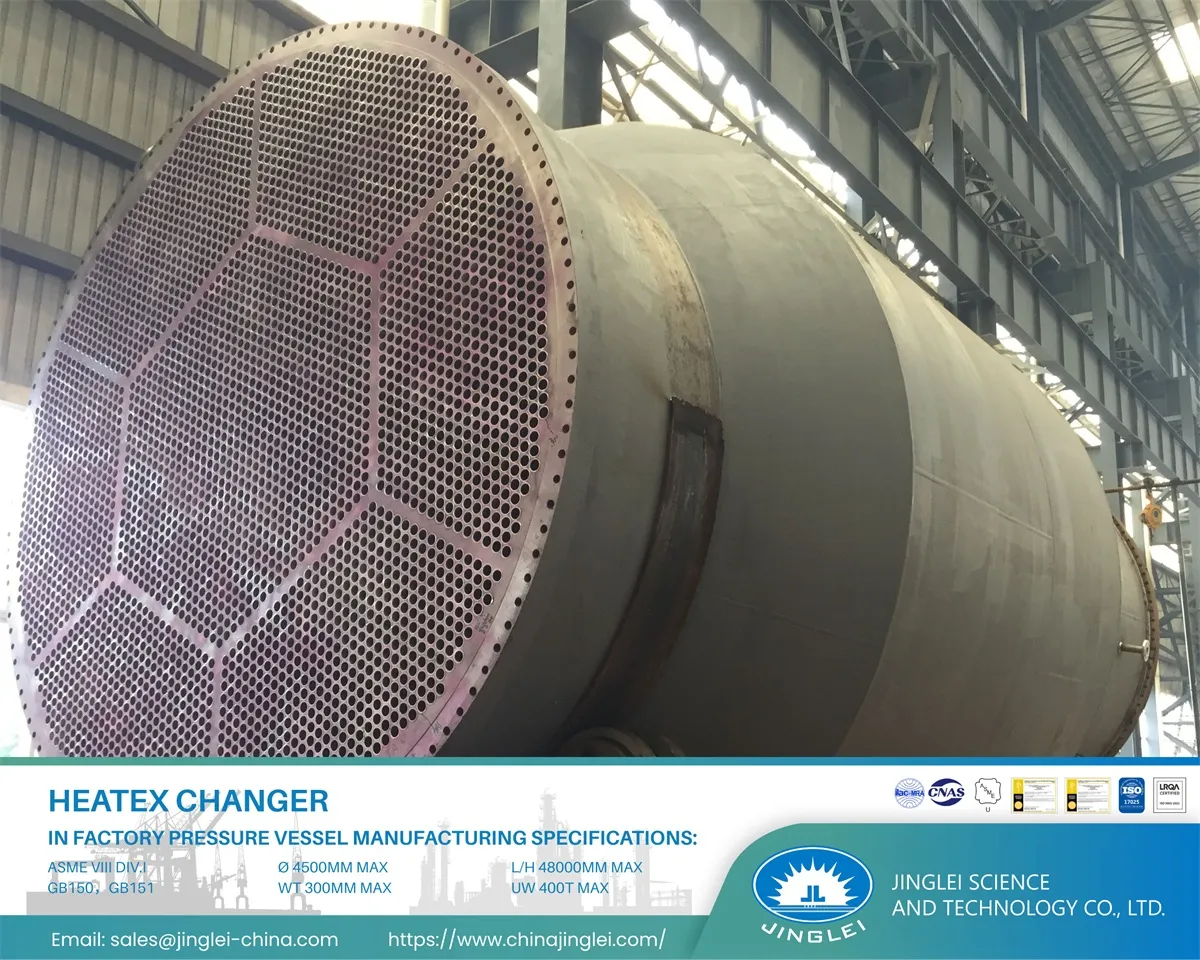

- — Heat Exhanger

As a specialized manufacturer in the field of pressure vessels, our company has established a comprehensive manufacturing system for high-efficiency heat exchange equipment.

In response to demanding operating conditions, we focus on the production of large shell-and-tube heat exchangers using titanium and titanium alloy tubes, achieving a strong competitive advantage in corrosive environments such as saline-alkali chemical processing and wastewater treatment. For applications requiring enhanced corrosion protection, we also provide heat exchanger cladding solutions that extend service life in severe chemical and thermal processes. In particular, within multi-effect vacuum evaporation and MVR evaporation systems, we have delivered a wide range of efficient and reliable heat exchangers—including systems integrated with liquid-to-liquid heat exchanger configurations and specialized liquid heat exchanger loops—that significantly improve user performance.

As a highly efficient and dependable thermal exchange device, shell-and-tube heat exchangers are widely used across various industries due to their excellent heat transfer performance and compact structure.

|

|

|

|

|

- — Storage Tank

The company has extensive experience in the field of storage tank and possesses professional on-site construction capabilities. We are capable of manufacturing and installing storage tanks and tank clusters with capacities ranging from 100m³ to 120,000m³. We have produced hundreds of various types of storage tanks for industries such as petrochemical, new energy chemicals, new materials, and water treatment.

|

|

|

|

|

- — Other Products List

Based on years of experience, we also provide a wide range of pressure vessels and auxiliary equipment, such as LPG Tanks, Amine Solution Activated Carbon Filters, Gas-Liquid Separators, Secondary Sulfur Condensers, Vacuum Towers, Feed Gas Heat Exchangers, Oxidized Asphalt Atmospheric Towers, Main Hydrocracking Reactors, High-Pressure Flash Drums, Slag Crushers, and Shift Gas Amine Scrubber Towers, covering diverse process requirements from petroleum refining to coal chemical industries.

| Product Name | Application Filed |

| Amine Solution Activated Carbon Filter | Chemical and petrochemical industries |

| Gas-Liquid Separator | Oil and gas extraction |

| Secondary Sulfur Condenser | Sulfur recovery units |

| Vacuum Tower | Refining and chemical industries |

| Feed Gas Heat Exchanger | Natural gas processing, refining, petrochemicals |

| Oxidized Asphalt Atmospheric Tower | Petroleum refining industry |

| Main Hydrocracking Reactor | Refining industry |

| High-Pressure Flash Drum | Oil refining and chemical industries |

| Slag Crusher | Coal chemical industry |

| Shift Gas Amine Scrubber Tower | Coal chemical industry |

| Other |